- Home

- Injection Molding Defects

Common Injection Molding Defects and Tips for Prevention - Manufacturer

Are you looking for a reliable manufacturer and supplier of high-quality injection molded products in China? Look no further than {Company}. With state-of-the-art facilities and a team of experienced professionals, we specialize in producing top-notch injection molded products that meet the highest industry standards.

Our extensive range of products caters to various industries, including automotive, electronics, consumer goods, and more. We utilize advanced injection molding techniques to ensure precise and consistent production, resulting in superior-quality products every time.

At {Company}, we understand the importance of delivering defect-free products to our clients. Our rigorous quality control processes and inspection protocols help us identify and address any potential injection molding defects, ensuring that our customers receive flawless products.

Whether you need custom injection molded components or standard off-the-shelf products, we have the capabilities and expertise to meet your requirements. Trust {Company} as your preferred partner for all your injection molding needs.

Xiamen Guansheng Precision Machinery Co., Ltd.

Company News

Related News

Brief Introduction of Steel Materials

Introducing SteelTech: Your reliable source for high-quality steel materials. As a factory, we specialize in producing durable and reliable steel products.

Brief Introduction of Polycarbonate Materials

Introducing ClearShield Polycarbonate Sheets - durable, high-impact material for various applications. We are a leading factory with top-quality products.

Brief Introduction of Copper Materials

Copper Materials: A Concise Guide As a leading factory, we specialize in manufacturing high-quality copper materials for various industrial applications. Explore our range now!

Silicon Moulding Services for Customized

Get high-quality Silicon Moulding Services for Customized products at our factory. We specialize in creating unique and personalized items.

Brief Introduction of Stainless steel Materials

Stainless Steel Materials: Discover the durability and versatility of our stainless steel products. As a factory, we guarantee high-quality at competitive prices.

Precision Die Casting Service for Customized

Customized Precision Die Casting Service - We are a factory specializing in producing high-quality custom die-cast products for various industries.

Brief Introduction of POM Materials

Introducing our high-quality POM materials for various industrial applications. As a factory, we ensure top-notch products for your needs.

Brief Introduction of Aluminum Materials

Introducing our range of high-quality Aluminum Materials. As a factory, we specialize in producing and supplying premium aluminum products. #AluminumMaterials #FactoryDirect "Explore our factory's top-notch Aluminum Materials. We offer a wide range of products, carefully crafted for superior quality and durability. Shop now!

3D Printing Service for Customized

Get custom 3D printed products with our factory service. Create unique designs for personalized items with our 3D printing service.

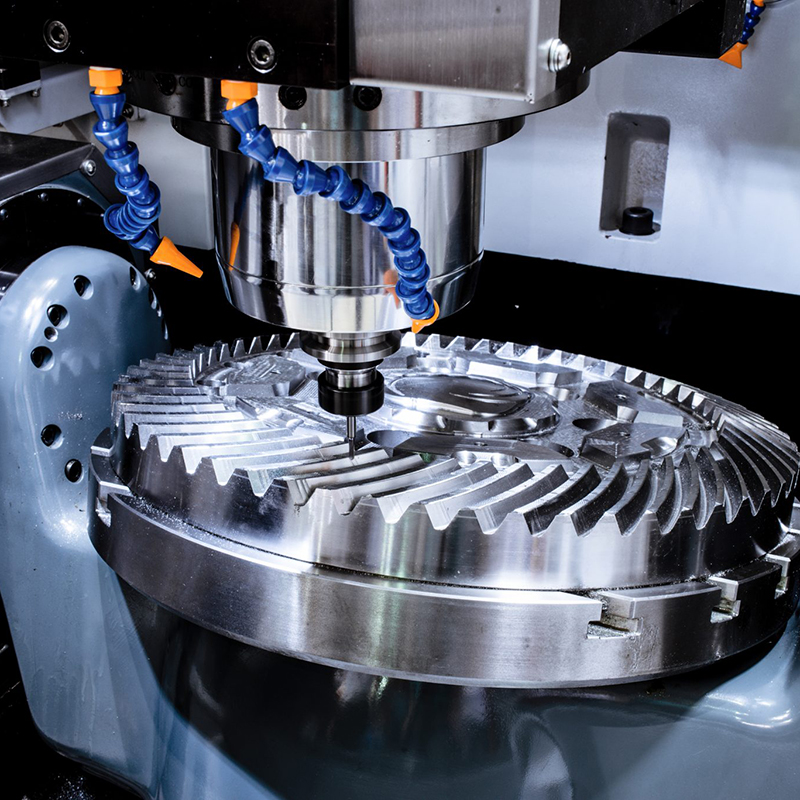

Custom Online CNC Machining Services

Get precision parts with our custom online CNC machining services. We are a factory specializing in high-quality, customized manufacturing solutions.

Finishing Services

Get flawless finishes with our Finishing Services. As a factory, we ensure top-quality results for all your products. Contact us today.

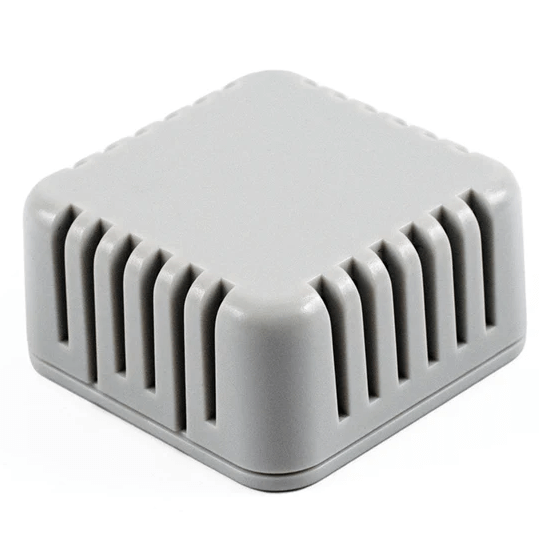

Injection Molding Services for Customized

Get high-quality Injection Molding Services for Customized products at our factory. We specialize in creating unique and tailored products to meet your needs.

Brief Introduction of PA Nylon Materials

Introducing our high-quality PA Nylon materials for various applications. As a factory, we ensure top-notch production and competitive pricing. Buy now!

Brief Introduction of Brass Materials

Introducing our high-quality brass materials, perfect for various industrial applications. As a leading factory, we guarantee top-notch products at competitive prices.

Brief Introduction of ABS Materials

ABS Materials is a versatile thermoplastic known for its high impact resistance and toughness. As a factory, we produce high-quality ABS materials for various industries.

- Common Injection Molding Defects: Tips from a Manufacturer

- Reviews

- Related Videos

Are you tired of dealing with injection molding defects in your products? Look no further, because our new and innovative solution is here to revolutionize the manufacturing process! Introducing our state-of-the-art injection molding technology, designed to drastically reduce the occurrence of defects in your products. Our advanced system has been meticulously engineered to offer precise control and consistency in the molding process, resulting in high-quality products with minimal defects. With the ability to correct defects such as warping, sink marks, and flow lines, our injection molding technology ensures that your products meet the highest standards of quality and durability. Say goodbye to costly rework and scrap, and hello to improved efficiency and cost-effectiveness. Whether you are in the automotive, medical, consumer goods, or electronics industry, our injection molding technology is the perfect solution for producing defect-free products that exceed customer expectations. You can trust in our cutting-edge technology to deliver superior results, time and time again. Don't let injection molding defects hold you back any longer. Upgrade to our innovative injection molding technology and experience the difference it can make in your manufacturing process. Say hello to flawless products and goodbye to defects – order our injection molding technology today!

I recently purchased a set of plastic products manufactured using injection molding, and I must say that the quality was disappointing. The products had several injection molding defects, such as sink marks, warping, and short shots. This resulted in a lack of uniformity and compromised the overall functionality of the products. I attempted to remedy some of the defects with sanding and reshaping, but it was a time-consuming and frustrating process. I would advise others to thoroughly inspect injection-molded products before purchasing to ensure they are free from defects.

I recently purchased a set of injection-molded products and was highly disappointed with the numerous defects present in the items. The most common defects I noticed were sink marks, warping, and uneven texture on the surface. These flaws greatly affected the overall appearance and functionality of the products. It is clear that the manufacturing process used for these items was not of high quality, leading to a subpar end result. I would advise potential buyers to thoroughly inspect injection-molded products for defects before purchasing to avoid disappointment. Overall, my experience with these products was less than satisfactory due to the injection molding defects.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours