Best Methods for Polishing Your Metal Surfaces

By:Admin

The process of polishing involves the removal of imperfections on the surface of a material, resulting in a smooth, glossy finish. This is essential in the manufacturing of various components, as it not only improves the aesthetic appeal of the products but also enhances their functionality and performance. Polishing is particularly important in the production of rapid prototypes, molds, and OEM engineering components, where precise and flawless finishes are required.

Xiamen Guansheng Precision Machinery Co., Ltd. is a global leader in the custom rapid prototyping, mold, and OEM engineering manufacturing industry. The company has a wealth of experience and expertise in producing high-quality components for a wide range of applications. With their commitment to quality first and short delivery times, they have built a strong reputation as a reliable and trusted manufacturer in the industry.

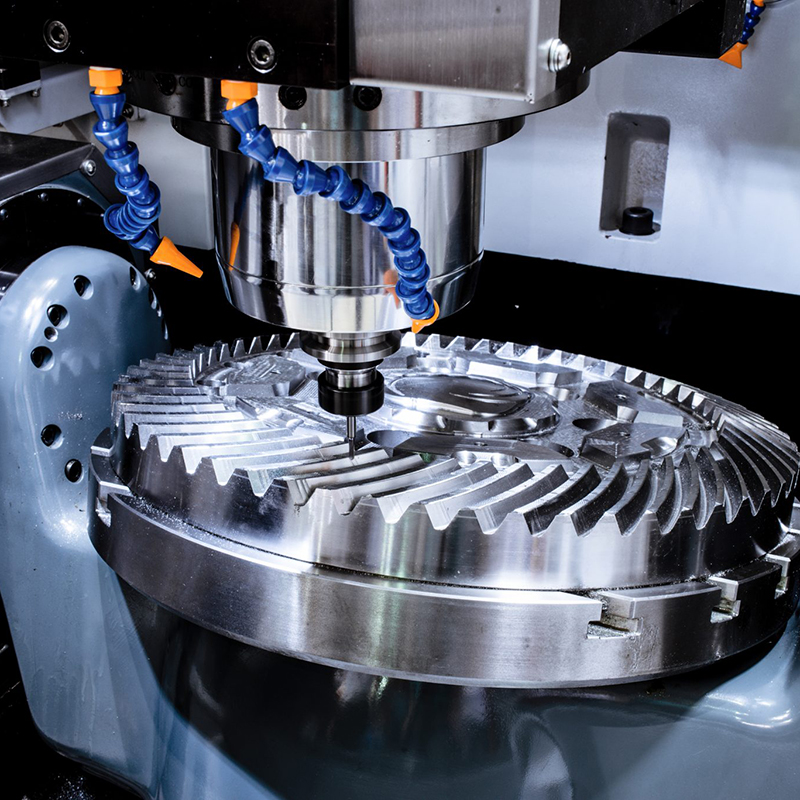

One of the key factors that contribute to Guansheng's success is their advanced manufacturing technology. The company has heavily invested in state-of-the-art machinery and equipment, allowing them to achieve the highest level of precision and accuracy in their manufacturing processes. This, in turn, enables them to produce components with superior finishes that meet the exact specifications and requirements of their clients.

In addition to their advanced technology, Guansheng also has a highly skilled team of engineers and technicians who are experts in their respective fields. These professionals have undergone rigorous training and have years of hands-on experience in the industry. Their expertise, combined with the latest manufacturing techniques, enables Guansheng to consistently deliver top-quality products to their clients.

Furthermore, Guansheng is committed to maintaining short delivery times, which is particularly important in the fast-paced manufacturing industry. They understand the importance of meeting deadlines and strive to complete projects within the stipulated time frame without compromising on quality. This commitment to efficiency and reliability has earned them the trust and loyalty of their clients, who rely on them for their manufacturing needs.

When it comes to the polishing process, Guansheng employs a variety of techniques and methods to achieve the desired finish on their components. They utilize cutting-edge polishing equipment and utilize the latest abrasives and compounds to achieve a smooth and uniform surface on their products. Whether it is rapid prototypes, molds, or OEM engineering components, Guansheng ensures that every detail is meticulously polished to perfection.

The importance of polishing in the manufacturing process cannot be overstated, especially in the production of high-precision components. A flawless finish not only enhances the visual appeal of the products but also improves their functionality and performance. With their commitment to quality and efficiency, combined with their advanced technology and skilled team, Guansheng has been able to maintain a competitive edge in the industry, serving as a trusted partner for their clients' manufacturing needs.

In conclusion, polishing is a critical part of the manufacturing process, particularly in the production of rapid prototypes, molds, and OEM engineering components. Companies like Xiamen Guansheng Precision Machinery Co., Ltd. understand the significance of high-quality finishing and have been able to maintain a competitive advantage in the industry thanks to their advanced manufacturing technology and highly skilled team. Their commitment to quality first and short delivery times has solidified their reputation as a reliable and trusted manufacturer in the industry.

Company News & Blog

Durable and Impact-Resistant Polycarbonate: A Versatile Material for Various Applications

Polycarbonate – The Revolutionary Material Redefining the Future of ManufacturingIn today's rapidly evolving world of manufacturing, there is a constant demand for materials that are not only strong and durable but also lightweight and versatile. Polycarbonate is a material that perfectly fits these criteria, and its uses are only limited by the imagination. Developed in the 1950s, polycarbonate has since become a popular choice for a wide range of applications, from safety glasses and medical devices to electronic components and even bulletproof glass.Polycarbonate is a type of thermoplastic polymer that is known for its exceptional impact resistance and transparency. Its high-impact strength makes it virtually unbreakable, making it an ideal material for use in areas where safety is of utmost importance. It is also highly resistant to heat and can withstand high temperatures without deforming or breaking, making it a perfect choice for use in electronic devices and automotive parts.One of the leading manufacturers of polycarbonate is {}. They have been at the forefront of the industry, continuously developing new and innovative ways to use this remarkable material. With a focus on research and development, they have been able to create polycarbonate products that are not only durable and reliable but also sustainable and environmentally friendly.{} offers a wide range of polycarbonate products, catering to a diverse set of industries and applications. From multi-wall polycarbonate sheets that are used in construction and architecture to polycarbonate films used in electronics and packaging, they have a solution for every need. Their commitment to quality and innovation has earned them a reputation as a trusted partner in the manufacturing industry.One of the key advantages of polycarbonate is its versatility. It can be easily molded into different shapes and sizes, allowing for a wide range of design possibilities. This flexibility makes it a popular choice for designers and engineers looking to create products that are both functional and visually appealing. In addition, its light weight makes it ideal for use in applications where weight is a concern, such as in the aerospace and automotive industries.Another important characteristic of polycarbonate is its excellent optical properties. It is highly transparent and can transmit light with minimal distortion, making it a popular choice for applications where clarity and visibility are crucial. This makes it an ideal material for use in windows, skylights, and displays, as well as in medical devices and optical lenses.In addition to its physical properties, polycarbonate is also known for its sustainability. It is a recyclable material, and {} has been proactive in promoting the use of recycled polycarbonate in their products. This commitment to sustainability is aligned with the growing demand for environmentally friendly materials, making polycarbonate an attractive choice for companies looking to reduce their carbon footprint.The future of manufacturing is constantly evolving, and polycarbonate is at the forefront of this revolution. With its exceptional properties and endless potential, it is redefining the way products are designed and manufactured. As the demand for lightweight, durable, and sustainable materials continues to grow, polycarbonate will undoubtedly play a key role in shaping the future of manufacturing.In conclusion, polycarbonate is a material that has truly revolutionized the way products are made. With its exceptional properties and versatility, it has become an indispensable material in a wide range of industries. As companies like {} continue to innovate and push the boundaries of what is possible with polycarbonate, there is no doubt that this remarkable material will continue to redefine the future of manufacturing for years to come.

High-Quality CNC Aluminum Parts Made in China for Various Industries

Xiamen Guansheng Precision Machinery Co., Ltd. has recently announced the launch of their new product line, China CNC Aluminum Parts. With the growing demand for high-quality, precision-machined parts in the global market, Guansheng’s new offering is set to make waves in the manufacturing industry.As an experienced global custom rapid prototyping, mold, and OEM engineering manufacturer, Xiamen Guansheng Precision Machinery Co., Ltd. has built a reputation for delivering top-notch products and services. With advanced manufacturing technology and a highly skilled team, the company has always maintained a competitive advantage with a focus on quality first and short delivery times.The new China CNC Aluminum Parts are a testament to Guansheng’s commitment to innovation and excellence. These parts are manufactured using the latest CNC machining technology, ensuring precise and consistent results. Aluminum is known for its lightweight, durable, and corrosion-resistant properties, making it an ideal material for a wide range of applications.With the launch of the China CNC Aluminum Parts, Guansheng aims to cater to the needs of industries such as automotive, aerospace, electronics, and more. These parts can be used in various components, including enclosures, brackets, heat sinks, and other critical elements of machinery and equipment.One of the key highlights of Guansheng’s CNC Aluminum Parts is the high level of customization available. Customers can choose from a wide range of sizes, shapes, and finishes to meet their specific requirements. This flexibility allows for the creation of bespoke parts tailored to the unique needs of different applications.Furthermore, Guansheng ensures that all CNC Aluminum Parts undergo rigorous quality control measures to guarantee precision and reliability. The company’s dedication to maintaining strict quality standards is reflected in the performance and durability of the parts, ultimately leading to customer satisfaction and trust.In addition to the quality of the parts, Guansheng also prioritizes speedy delivery to meet the demands of its global clientele. The company understands the importance of timely production and delivery in today’s fast-paced industry, and thus, it has streamlined its processes to ensure quick turnaround times without compromising on quality.The introduction of the China CNC Aluminum Parts marks a significant milestone for Xiamen Guansheng Precision Machinery Co., Ltd. and reinforces its position as a leader in the manufacturing and engineering sector. With a focus on customer-centric solutions and an unwavering commitment to excellence, the company is set to make a substantial impact on the market with its latest offering.Furthermore, the company’s dedication to sustainability and environmental responsibility is evident in its manufacturing processes. Guansheng ensures that its operations adhere to eco-friendly practices, minimizing waste and reducing its carbon footprint. This conscientious approach aligns with the increasing global focus on sustainability, positioning the company as a responsible and forward-thinking industry player.As the global manufacturing landscape continues to evolve, Xiamen Guansheng Precision Machinery Co., Ltd. remains at the forefront of innovation and technological advancement. The launch of the China CNC Aluminum Parts is a testament to the company’s ongoing commitment to meeting the diverse needs of its customers while upholding the highest standards of quality and excellence.With its extensive experience, cutting-edge technology, and a customer-centric approach, Guansheng is poised to carve a niche for itself in the competitive market for precision-machined parts. The company’s dedication to continuous improvement and innovation bodes well for its future prospects, and the China CNC Aluminum Parts are a testament to its unwavering pursuit of excellence.

High-Quality CNC Machining Shop in China for Precision Parts Manufacturing

China CNC Machining Shop Implements Advanced Manufacturing Technology for Rapid Prototyping and OEM Engineering ManufacturingXiamen, China - As the demand for custom rapid prototyping, mold, and OEM engineering manufacturing continues to rise globally, Xiamen Guansheng Precision Machinery Co., Ltd. has announced the implementation of advanced manufacturing technology in its CNC machining shop. With an experienced team and a commitment to quality and efficiency, the company is set to maintain its competitive advantage in the industry.Guansheng Precision Machinery has been a leading manufacturer in the field of custom rapid prototyping, mold, and OEM engineering manufacturing for many years. With a focus on providing high-quality products and short delivery times, the company has built a strong reputation among its global clientele."We are constantly looking for ways to improve our manufacturing processes and capabilities in order to better serve our customers," said a spokesperson for Guansheng Precision Machinery. "By implementing advanced manufacturing technology in our CNC machining shop, we are able to offer even faster prototyping and production of OEM components, without compromising on quality."The CNC machining shop at Guansheng Precision Machinery is equipped with state-of-the-art equipment and machinery, allowing for precision and efficiency in the production of custom parts and components. The company's highly skilled team of engineers and technicians are adept at using the latest manufacturing technology to create prototypes and molds with intricate designs and tight tolerances."We understand the importance of rapid prototyping and quick turnaround times in today's fast-paced manufacturing industry," the spokesperson added. "By leveraging advanced manufacturing technology, we are able to meet the increasing demand for custom parts and components, while ensuring that our products meet the highest standards of quality."In addition to rapid prototyping and mold manufacturing, Guansheng Precision Machinery also specializes in OEM engineering manufacturing, providing customized solutions for a wide range of industries. The company's ability to produce high-quality OEM components with short lead times has made it a preferred partner for many global companies."OEM engineering manufacturing requires a high degree of precision and attention to detail," said the spokesperson. "Our advanced manufacturing technology allows us to consistently deliver reliable and customized OEM components to our customers, helping them to streamline their production processes and meet their business objectives."Guansheng Precision Machinery's commitment to quality first and short delivery times has set it apart from its competitors in the industry. With the implementation of advanced manufacturing technology in its CNC machining shop, the company is poised to further strengthen its position as a leading global manufacturer of custom rapid prototyping, mold, and OEM engineering manufacturing."We are confident that our investment in advanced manufacturing technology will enable us to continue meeting the evolving needs of our customers, while upholding the highest standards of quality and efficiency," the spokesperson concluded.As the demand for custom rapid prototyping, mold, and OEM engineering manufacturing continues to grow, Guansheng Precision Machinery's dedication to leveraging advanced manufacturing technology positions the company as a reliable and innovative partner for businesses seeking high-quality, customized components. With a focus on quality first and short delivery times, the company remains committed to meeting the unique needs of its global clientele.

High-Quality CNC Machining Parts for Precision Manufacturing

Xiamen Guansheng Precision Machinery Co., Ltd. is making waves in the manufacturing industry with their high-quality precision CNC machining parts. The company, known for their advanced manufacturing technology and highly skilled team, has established itself as a global leader in custom rapid prototyping, mold, and OEM engineering manufacturing.The precision CNC machining parts manufactured by Xiamen Guansheng are an integral component in a wide range of products, from consumer electronics to automotive components and medical devices. These parts are known for their exceptional accuracy and durability, making them a popular choice among manufacturers looking for reliable and high-performance components.One of the key differentiators for Xiamen Guansheng is their commitment to quality first and short delivery times. By investing in state-of-the-art machinery and employing a team of experienced and dedicated professionals, the company is able to consistently deliver precision CNC machining parts that meet the highest industry standards. This focus on quality has earned Xiamen Guansheng a stellar reputation among their clients, who value the reliability and performance of their products.In addition to their commitment to quality, Xiamen Guansheng also places a strong emphasis on providing exceptional customer service. The company works closely with their clients to understand their specific needs and requirements, ensuring that the precision CNC machining parts they deliver are tailored to meet the exact specifications of their customers. This personalized approach has helped Xiamen Guansheng establish long-lasting relationships with their clients, who appreciate the attention to detail and dedication to customer satisfaction.Xiamen Guansheng's dedication to excellence has not gone unnoticed in the industry. The company has received numerous accolades and awards for their innovative approach to manufacturing and their ability to consistently deliver high-quality precision CNC machining parts. These accolades serve as a testament to the company's unwavering commitment to excellence and their position as a leader in the manufacturing industry.Looking ahead, Xiamen Guansheng is poised for continued growth and success. The company is continuously investing in new technologies and equipment to further enhance their manufacturing capabilities and expand their product offerings. By staying at the forefront of industry trends and innovations, Xiamen Guansheng is well-positioned to meet the evolving needs of their clients and maintain their competitive edge in the market.As the demand for precision CNC machining parts continues to grow, Xiamen Guansheng is dedicated to meeting this demand with their cutting-edge manufacturing capabilities and unwavering commitment to quality. With a strong focus on customer satisfaction and a proven track record of delivering exceptional products, Xiamen Guansheng is positioned to remain a key player in the global manufacturing industry for years to come.

The Ultimate Guide to Understanding the Purpose of CNC Machines

In today's fast-paced manufacturing industry, the need for precision and efficiency is more important than ever. This is where CNC (Computer Numerical Control) machines come into play. CNC machines have revolutionized the way manufacturers produce components and products, making the process faster, more accurate, and more cost-effective.A CNC machine is a computer-controlled manufacturing tool that can create intricate and complex parts with a high level of precision. These machines use computer-aided design (CAD) software to generate the required tool paths and then translate those paths into precise movements of the cutting or shaping tools. As a result, CNC machines can produce highly accurate and repeatable parts with minimal human intervention.The use of CNC machines has become increasingly popular in the manufacturing industry due to their numerous advantages. One of the key benefits of CNC machining is its ability to produce high-quality parts with tight tolerances. This makes CNC machines an ideal choice for industries such as aerospace, automotive, and medical, where precision and accuracy are of utmost importance.Additionally, CNC machines can also greatly increase productivity and efficiency. With the ability to run continuously and produce large quantities of parts with minimal downtime, manufacturers can significantly reduce lead times and increase their overall output. This can ultimately lead to cost savings and a competitive edge in the market.Another advantage of CNC machines is their versatility. These machines can be used to produce a wide range of components, from simple to highly complex geometries, and can work with various materials, including metals, plastics, and composites. This versatility makes CNC machines a valuable asset for manufacturers with diverse production requirements.In recent years, the demand for CNC machines has been on the rise, driven by the need for advanced manufacturing technologies. As a response to this demand, the company {} has been at the forefront of developing cutting-edge CNC machines that offer unmatched precision, speed, and reliability.{} is a leading manufacturer of CNC machines with a strong focus on innovation and quality. With a history of providing high-performance machining solutions, the company has gained a reputation for delivering state-of-the-art equipment that meets the evolving needs of the manufacturing industry.The company's CNC machines are designed to deliver exceptional accuracy and repeatability, allowing manufacturers to produce parts with the highest level of precision. Furthermore, their machines are equipped with advanced features and technology that enable efficient and reliable operation, making them an ideal choice for a wide range of manufacturing applications.In addition to their technical capabilities, {} is also known for their commitment to customer satisfaction. The company offers comprehensive support and services to ensure that their customers can maximize the performance and lifespan of their CNC machines. This includes training programs, technical assistance, and maintenance services to keep the equipment running at its best.Looking ahead, the company is continuously investing in research and development to further enhance the capabilities of their CNC machines. With a focus on incorporating the latest technological advancements and industry trends, {} aims to stay ahead of the curve and continue to provide cutting-edge solutions for the manufacturing industry.In conclusion, CNC machines play a crucial role in modern manufacturing, offering unmatched precision, efficiency, and versatility. As the demand for advanced machining technologies continues to grow, companies like {} are at the forefront of developing innovative CNC machines that meet the evolving needs of the industry. Through their commitment to excellence and customer satisfaction, {} is well-positioned to shape the future of CNC machining and empower manufacturers to achieve new levels of productivity and quality.

High-quality CNC machine components for precision engineering applications

In the world of manufacturing and industrial production, precision and efficiency are crucial. This is why the recent introduction of the state-of-the-art CNC machine components by {Company} has caught the attention of industry experts and manufacturers alike. This new range of components is set to revolutionize the production process, making it faster, more accurate, and more cost-effective than ever before.{Company} has been a leading player in the manufacturing and distribution of industrial equipment for over two decades. With a strong focus on innovation and cutting-edge technology, the company has built a reputation for delivering high-quality, reliable products that meet the evolving needs of the industry. The introduction of their new CNC machine components is a testament to their commitment to staying ahead of the curve and providing their customers with the best possible solutions.The new range of CNC machine components includes a variety of essential parts and accessories that are designed to enhance the performance of CNC machines. These components have been meticulously engineered using the latest manufacturing techniques and materials to ensure optimal performance and longevity. From cutting tools and rotary tables to spindle units and cooling systems, the new range covers a wide spectrum of components that are essential for the smooth operation of CNC machines.One of the key highlights of these components is their advanced design and precision engineering. The company has invested heavily in research and development to create components that meet the highest standards of accuracy and reliability. This means that manufacturers can expect consistent and precise performance from their CNC machines, resulting in superior quality end products and reduced downtime for maintenance and repairs.Furthermore, the new CNC machine components are designed to be highly versatile and adaptable to different manufacturing applications. Whether it's for milling, turning, grinding, or any other machining operation, these components are engineered to deliver top-notch performance across a wide range of tasks. This level of flexibility is invaluable for manufacturers who need to optimize their production processes and adapt to changing market demands.In addition to their exceptional performance, the new CNC machine components also prioritize user-friendly features and ease of maintenance. The company has incorporated smart design elements that make installation, operation, and upkeep as convenient as possible. This ensures that manufacturers can maximize the productivity of their CNC machines without being burdened by complex maintenance routines or technical difficulties.With the introduction of these cutting-edge CNC machine components, {Company} is poised to make a significant impact on the manufacturing industry. By providing manufacturers with the tools they need to enhance their production processes, the company is empowering them to stay competitive in today's fast-paced market. As industry professionals continue to seek ways to streamline their operations and improve their output, the new range of components from {Company} stands out as a game-changing solution.In conclusion, the introduction of the new CNC machine components by {Company} marks a significant milestone in the evolution of industrial manufacturing technology. With their focus on innovation, precision, and user-friendly design, these components are set to redefine the capabilities of CNC machines and revolutionize the way manufacturers approach production. As the industry continues to evolve, {Company} remains at the forefront, setting new standards in quality and performance.

Expert Guide to Custom Molding Manufacturing

Xiamen Guansheng Precision Machinery Co., Ltd. has recently announced exciting developments in its custom molding manufacturing capabilities, further solidifying its position as a global leader in rapid prototyping, mold and OEM engineering manufacturing. With a commitment to quality and a focus on short delivery times, the company is well-positioned to meet the evolving needs of its clients around the world.The custom molding manufacturing process is a critical component of many industries, including automotive, aerospace, consumer products, and more. As the demand for customized components continues to grow, so too does the need for reliable and efficient manufacturing solutions. Recognizing this trend, Xiamen Guansheng Precision Machinery Co., Ltd. has invested in advanced manufacturing technology and assembled a highly skilled team to ensure that it remains at the forefront of the industry.One of the key factors that sets Xiamen Guansheng Precision Machinery Co., Ltd. apart from its competitors is its unwavering commitment to quality. The company understands that its clients rely on its products to meet the highest standards, and it takes this responsibility seriously. By employing the latest manufacturing techniques and rigorous quality control measures, Xiamen Guansheng Precision Machinery Co., Ltd. ensures that each custom molding project meets or exceeds the expectations of its clients.In addition to quality, Xiamen Guansheng Precision Machinery Co., Ltd. also places a strong emphasis on short delivery times. The company understands that in today's fast-paced business environment, time is of the essence. By streamlining its manufacturing processes and optimizing its supply chain, Xiamen Guansheng Precision Machinery Co., Ltd. is able to deliver custom molding products to its clients in a timely manner, helping them stay ahead of the competition.The company's custom molding manufacturing capabilities encompass a wide range of materials and production techniques. Whether clients require injection molding, compression molding, rotational molding, or any other method, Xiamen Guansheng Precision Machinery Co., Ltd. has the expertise and resources to deliver. The company's ability to work with various materials, including plastics, metals, and composites, further enhances its versatility and appeal to a broad spectrum of industries.Moreover, Xiamen Guansheng Precision Machinery Co., Ltd. understands that effective communication is essential to the success of any custom molding project. The company works closely with its clients from the initial design phase through to production, ensuring that their specific requirements are met at every stage. By fostering a collaborative and transparent relationship with its clients, Xiamen Guansheng Precision Machinery Co., Ltd. is able to deliver custom molding solutions that truly align with their needs and expectations.Looking ahead, Xiamen Guansheng Precision Machinery Co., Ltd. is committed to continually pushing the boundaries of custom molding manufacturing. The company is dedicated to exploring new technologies and techniques that will further enhance its capabilities and enable it to meet the evolving needs of its clients. By staying ahead of industry trends and embracing innovation, Xiamen Guansheng Precision Machinery Co., Ltd. is well-positioned to continue serving as a trusted partner for custom rapid prototyping, mold, and OEM engineering manufacturing.In conclusion, Xiamen Guansheng Precision Machinery Co., Ltd. is an experienced and reputable global custom molding manufacturing company that is dedicated to quality and customer satisfaction. With a focus on advanced manufacturing technology, a highly skilled team, and a commitment to short delivery times, the company is well-prepared to meet the diverse and evolving needs of its clients around the world. As the demand for custom molding solutions continues to grow, Xiamen Guansheng Precision Machinery Co., Ltd. is poised to remain at the forefront of the industry, delivering innovative and reliable manufacturing solutions.

High-Quality CNC Machining Services for the Manufacturing Industry

CNC Machining Industries (CMI) is a leading manufacturer and supplier of precision CNC machined components for a wide range of industries. With over 20 years of experience in the industry, CMI has built a strong reputation for delivering high-quality, reliable products to its customers. The company's state-of-the-art manufacturing facility is equipped with the latest CNC machining technology, allowing them to produce complex and intricate components with exceptional accuracy and precision.CMI's team of highly skilled engineers and technicians have extensive experience in CNC machining, and are able to work with a variety of materials, including aluminum, steel, titanium, and plastics. The company's commitment to quality and customer satisfaction has made them a trusted partner for many leading companies in industries such as aerospace, automotive, medical, and defense.In recent news, CMI has announced plans to expand its manufacturing capabilities in order to meet the growing demand for precision machined components. The company has invested in new CNC machining equipment, including multi-axis mills and lathes, as well as advanced inspection and quality control systems. This expansion will allow CMI to increase its production capacity and streamline its manufacturing processes, ultimately enabling them to serve a larger customer base and take on more complex projects."We are excited to announce our expansion plans as we continue to grow and evolve as a company," said [Name], CEO of CMI. "With the increasing demand for high-quality precision components, we saw the need to invest in new technology and equipment to ensure that we can continue to meet the needs of our customers and deliver the excellence that they have come to expect from us."This expansion is part of CMI's long-term strategy to strengthen its position in the market and remain at the forefront of CNC machining technology. By investing in cutting-edge equipment and expanding their manufacturing capabilities, CMI is poised to deliver even greater value to its customers and take on more challenging projects in the future.In addition to expanding their manufacturing capabilities, CMI has also focused on enhancing its quality management systems to ensure that every component produced meets the highest standards of precision and reliability. The company is ISO 9001 certified and maintains rigorous inspection and testing procedures throughout the machining process to guarantee the quality of their products.Furthermore, CMI places a strong emphasis on customer satisfaction and aims to build long-lasting partnerships with its clients. The company works closely with its customers from the initial design phase through to production, providing expert advice and technical support to ensure that the final product meets their exact specifications."We take great pride in the relationships we have built with our customers over the years," [Name] added. "Our commitment to excellence and customer satisfaction is at the core of everything we do, and we will continue to work tirelessly to exceed our customers' expectations."CMI's dedication to providing high-quality CNC machined components and their ongoing investment in advanced manufacturing technology position them as a leading player in the industry. With a focus on innovation, precision, and customer satisfaction, CMI is well-equipped to meet the evolving needs of the market and drive the industry forward.As CMI continues to expand its manufacturing capabilities and enhance its quality management systems, the company is poised to solidify its position as a trusted partner for precision CNC machined components across a wide range of industries. With a strong commitment to excellence and customer satisfaction, CMI is well-positioned for continued success in the years to come.

Aluminum Anodizing Services Near Me: Find Local Experts in Anodizing Aluminum

Anodizing Aluminum Near Me:In today's fast-paced manufacturing industry, the demand for high-quality and durable aluminum products is on the rise. Anodizing is a process that enhances the natural properties of aluminum by creating a protective and decorative oxide layer on its surface. This process not only adds to the aesthetic appeal of aluminum products but also increases their resistance to corrosion and wear.[Company Name] is a leading provider of anodizing services, offering a wide range of options for businesses looking to improve the quality and longevity of their aluminum products. With state-of-the-art facilities and a team of experienced professionals, [Company Name] has built a reputation for delivering superior anodizing solutions for various industries.Located near [Your Location], [Company Name] is conveniently situated to serve local businesses in the area. Whether it's automotive parts, architectural components, or consumer electronics, [Company Name] can cater to the anodizing needs of diverse industries. Their expertise in anodizing aluminum allows them to provide customized solutions that meet the specific requirements of their clients.The anodizing process offered by [Company Name] involves immersing the aluminum parts in an electrolyte solution and passing an electric current through it. This creates an oxide layer on the surface of the aluminum, which can then be dyed or left in its natural state. The result is a durable and aesthetically pleasing finish that enhances the overall value of the products.In addition to standard anodizing services, [Company Name] also offers hard coat anodizing, which further increases the hardness and wear resistance of the aluminum. This makes the treated products ideal for applications that require superior durability and performance.One of the key advantages of choosing [Company Name] for anodizing aluminum near [Your Location] is their commitment to quality and customer satisfaction. Their team works closely with clients to understand their specific needs and deliver solutions that exceed expectations. Furthermore, [Company Name] prioritizes environmental sustainability, ensuring that their anodizing processes adhere to the highest standards of environmental responsibility.With a focus on continuous improvement and innovation, [Company Name] stays abreast of the latest advancements in anodizing technology. This enables them to offer cutting-edge solutions that align with the evolving demands of the market. Additionally, their strict quality control measures guarantee that every anodized product meets the highest industry standards.As a reliable partner for businesses seeking anodizing aluminum near [Your Location], [Company Name] is dedicated to providing efficient and cost-effective services. Their streamlined processes and attentive customer support make them a preferred choice for local manufacturers and fabricators.In conclusion, the demand for anodizing aluminum services near [Your Location] is met with the expertise and professionalism of [Company Name]. Their comprehensive anodizing solutions, coupled with a steadfast commitment to quality and sustainability, position them as a trusted partner for businesses in need of superior aluminum finishing. With [Company Name], clients can expect exceptional results that enhance the performance and visual appeal of their aluminum products.

CNC Lathe Process in China: A Comprehensive Guide

China CNC Lathe Process Revolutionizes ManufacturingIn the ever-evolving world of manufacturing, China has long been at the forefront of innovation and technology. One such innovation that is making waves in the industry is the China CNC Lathe Process. This cutting-edge technology has revolutionized the way that parts are manufactured, providing faster production times, higher precision, and increased efficiency.The China CNC Lathe Process is a computer-controlled machining process that utilizes advanced software and cutting-edge machinery to produce high-quality, precision parts. This process has completely transformed the manufacturing industry, allowing for greater efficiency and accuracy in the production of parts and components.One company that has fully embraced the China CNC Lathe Process is {}. As a leading manufacturer in the industry, {} has always been at the forefront of adopting new technologies to improve their manufacturing processes.With the integration of the China CNC Lathe Process into their production line, {} has been able to greatly increase their production capacity and efficiency. This has allowed them to meet the growing demands of their customers while maintaining the high quality and precision that they are known for.The CNC Lathe Process has allowed {} to streamline their production process, reduce lead times, and improve overall quality. This has not only benefited the company but has also resulted in greater customer satisfaction and loyalty.The precision and accuracy of the China CNC Lathe Process have also allowed {} to take on more complex projects and produce intricate parts and components with ease. The advanced software and machinery involved in the process have greatly expanded the capabilities of the company, allowing them to take on a wider range of projects and provide a more diverse array of products to their customers.By fully embracing the China CNC Lathe Process, {} has been able to stay ahead of the competition and solidify their position as a leader in the industry. The company's commitment to innovation and technology has allowed them to continuously improve their manufacturing processes and provide their customers with the highest quality products.In addition to benefiting {} as a company, the China CNC Lathe Process has also had a positive impact on the manufacturing industry as a whole. The increased efficiency and precision provided by this technology have set a new standard for the industry, pushing other companies to adopt similar processes in order to remain competitive.With the China CNC Lathe Process, the possibilities for manufacturing are endless. This technology has opened up new opportunities for companies to produce complex parts and components with unparalleled accuracy and efficiency. As more companies continue to adopt this innovative process, the manufacturing industry as a whole will see significant advancements in quality and productivity.As a company that has fully integrated the China CNC Lathe Process into their production line, {} is well-positioned to continue leading the industry in quality and efficiency. With their commitment to innovation and technology, they are sure to remain at the forefront of the manufacturing industry for years to come.